The Silent Threat Costing Data Centers Millions Every Year

Water leaks in data centers aren't like burst pipes in your basement. They're worse. A small leak can cascade into catastrophic downtime, equipment destruction, and costs that reach into the millions. Yet most data center operators still operate reactively, discovering problems only after they've already caused damage.

This is the exact problem that John Khazraee, founder of Mayim Flow, watched happen repeatedly during his 15-year career building infrastructure for IBM, Oracle, and Microsoft. He saw operators scramble when leaks appeared. He watched companies shut down servers, disrupt data services, and pour money into emergency remediation. And he realized something crucial: nobody was trying to prevent these leaks. They were just waiting for them to happen.

Data centers consume staggering amounts of water. A single large facility can use millions of gallons daily for cooling, humidification, and critical systems. That water flows through hundreds of miles of pipes, connections, and distribution systems. Each joint represents a potential failure point. Each pipe carries enough water to flood expensive equipment in minutes.

The risk isn't theoretical. Data center operators lose sleep over water management because the consequences are real, measurable, and expensive. Downtime alone can cost enterprise customers thousands of dollars per minute. Equipment replacement costs compound quickly. Then there's the reputational damage when services go down.

Mayim Flow's approach is fundamentally different from what exists today. Instead of waiting for leaks to develop, the company has built a system that predicts them. Using IoT sensors combined with edge-deployed machine learning models trained on years of industrial water system data, Mayim Flow can detect the early warning signs of failure. The company claims it can provide data center operators with 24 to 48 hours of advance notice that repairs will be needed.

That advance warning changes everything. It transforms a reactive crisis into a manageable maintenance task. It gives engineers time to schedule work during low-traffic periods. It prevents emergency shutdowns. It eliminates the scramble and the expensive cleanup.

Khazraee's willingness to turn down offers from major tech companies to pursue this vision suggests he believes in the opportunity. His team composition supports that conviction. Jim Wong, the chief strategy officer, brings decades of data center experience. Ray Lok, the CTO, has built his career around water management and IoT infrastructure. These aren't people dabbling in a side project. They're infrastructure specialists who've spent their professional lives understanding exactly why this problem matters.

Understanding the Data Center Water Crisis

Data centers represent the physical backbone of modern computing. They house the servers that power cloud services, store data, train AI models, and keep the internet running. And they need an enormous amount of water to function.

Water serves multiple critical purposes in data center operations. Cooling towers use water to dissipate the massive heat generated by thousands of densely packed servers. Humidification systems maintain precise humidity levels required for optimal equipment performance. Emergency systems use water for fire suppression. Support facilities need water for bathrooms, kitchens, and cleaning.

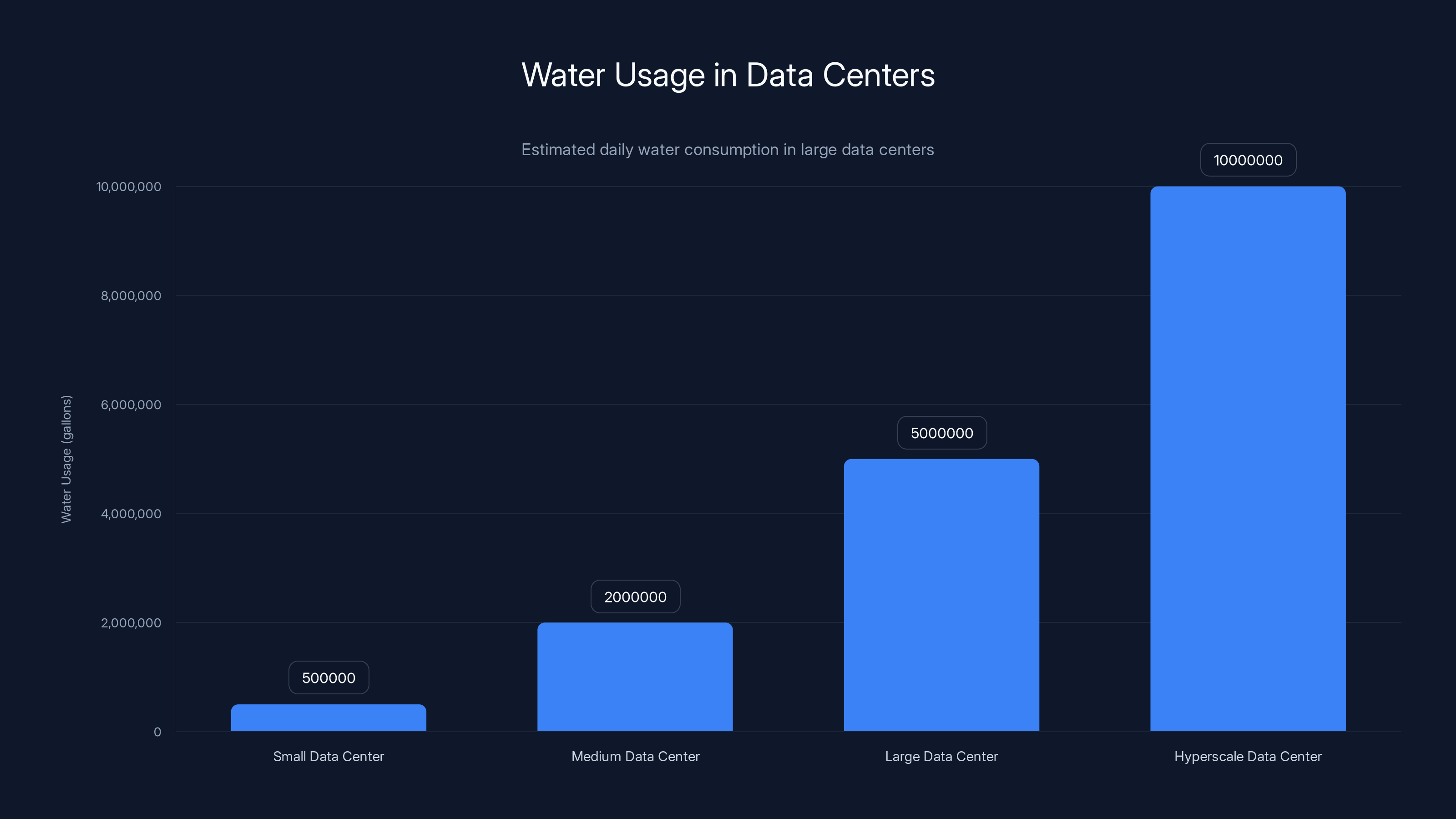

A large hyperscale data center might use between 1 million and 5 million gallons of water daily. Some estimates suggest that water usage could exceed 10 million gallons in the largest facilities. When you consider that a single undetected leak might discharge thousands of gallons per hour, the scale of potential disaster becomes clear.

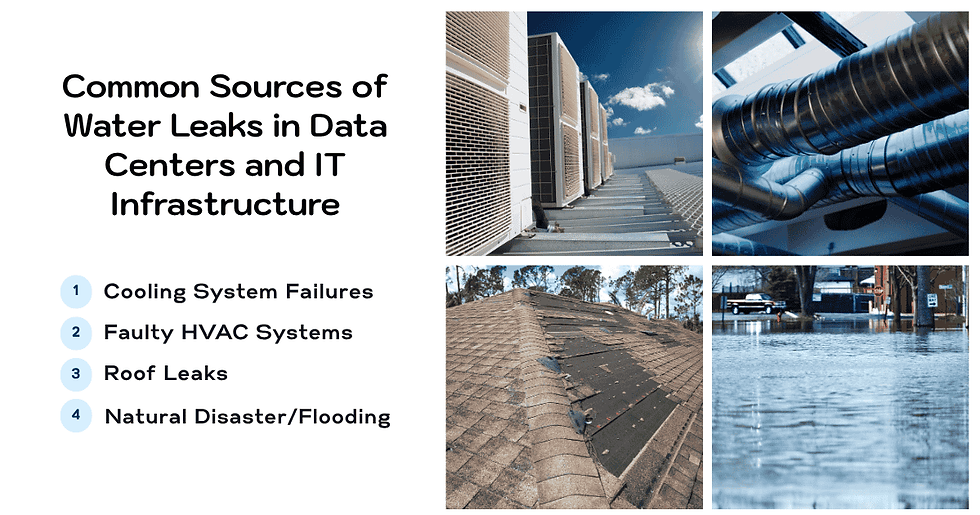

But the volume of water isn't the only problem. The complexity of data center water systems creates hidden vulnerabilities. Modern facilities often run multiple interconnected water systems in parallel. Cooling loops, chilled water distribution networks, humidification lines, and fire suppression pipes all coexist. Each system operates at different pressures, temperatures, and flow rates. Connections between these systems multiply failure points exponentially.

The materials used in these systems degrade over time. Corrosion from water chemistry, thermal stress from temperature cycling, and metal fatigue from pressure fluctuations all contribute to failures. A pipe that works perfectly on day one might develop microscopic cracks months later. These cracks grow until they become leaks. If nobody notices the early signs, the consequences accelerate.

Data center operators have historically managed this risk with simple detection methods. Operators walk around with clipboards checking for drips. They look for wet spots on floors or walls. They listen for unusual sounds in mechanical rooms. It's manual, slow, and fundamentally reactive. If a leak occurs at 2 AM on a Sunday, nobody might notice until morning.

When a leak does get discovered, the response is immediate crisis management. Engineers must first identify the exact source of the leak, which takes time and investigation. Then they need to isolate the problem, which might require shutting down portions of the affected system. If the leak has already damaged equipment, replacement becomes necessary. If water has reached electrical systems, the safety implications become severe.

The human cost is significant too. Data center operators stress about the risk constantly. They implement expensive preventative measures like redundant piping, backup cooling systems, and water treatment facilities. They hire additional staff to monitor systems more frequently. They purchase expensive insurance to cover potential losses. All of this adds up to real overhead that doesn't directly support business operations.

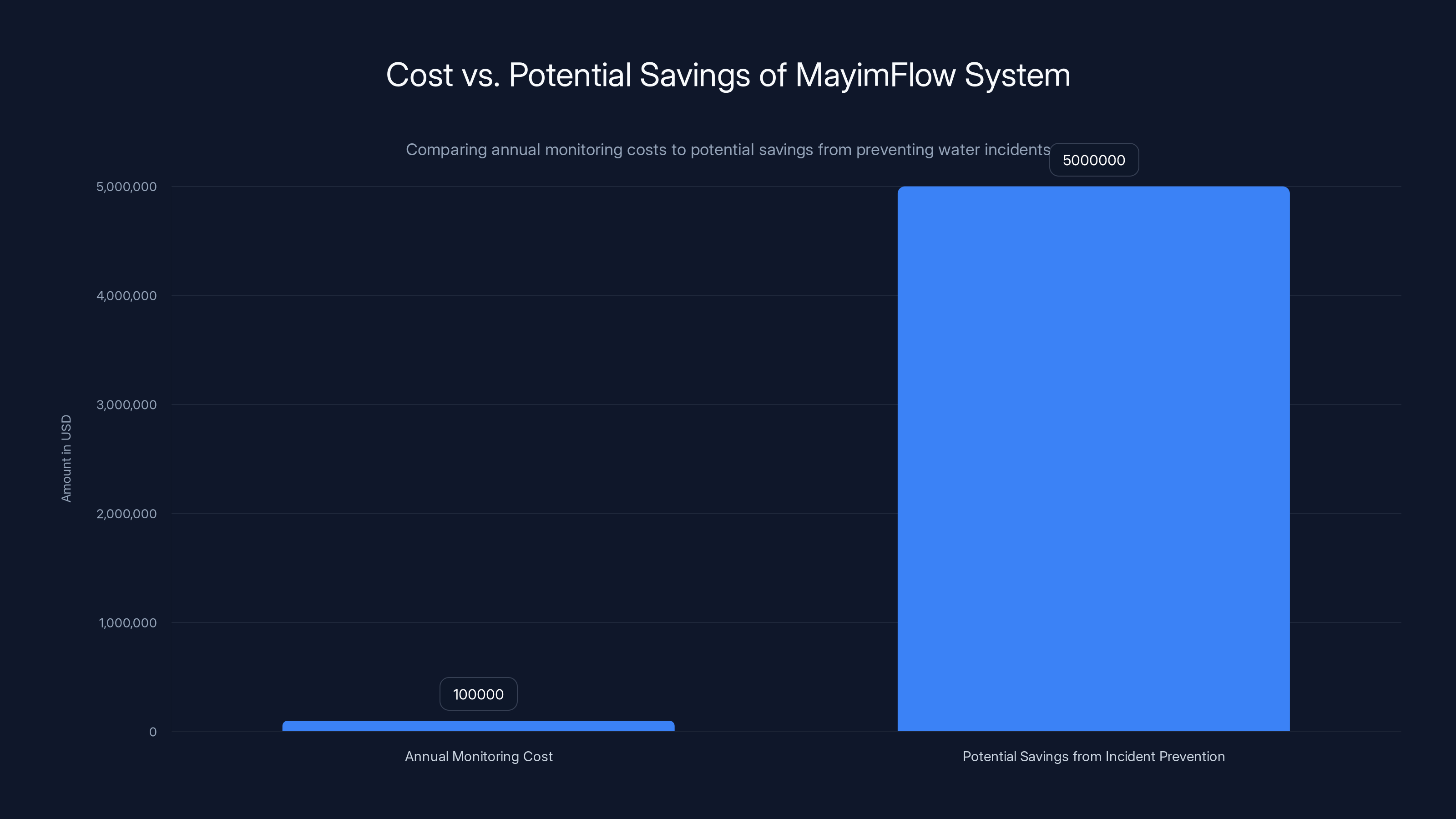

Implementing MayimFlow costs

The Mayim Flow Solution: Predictive Water Monitoring

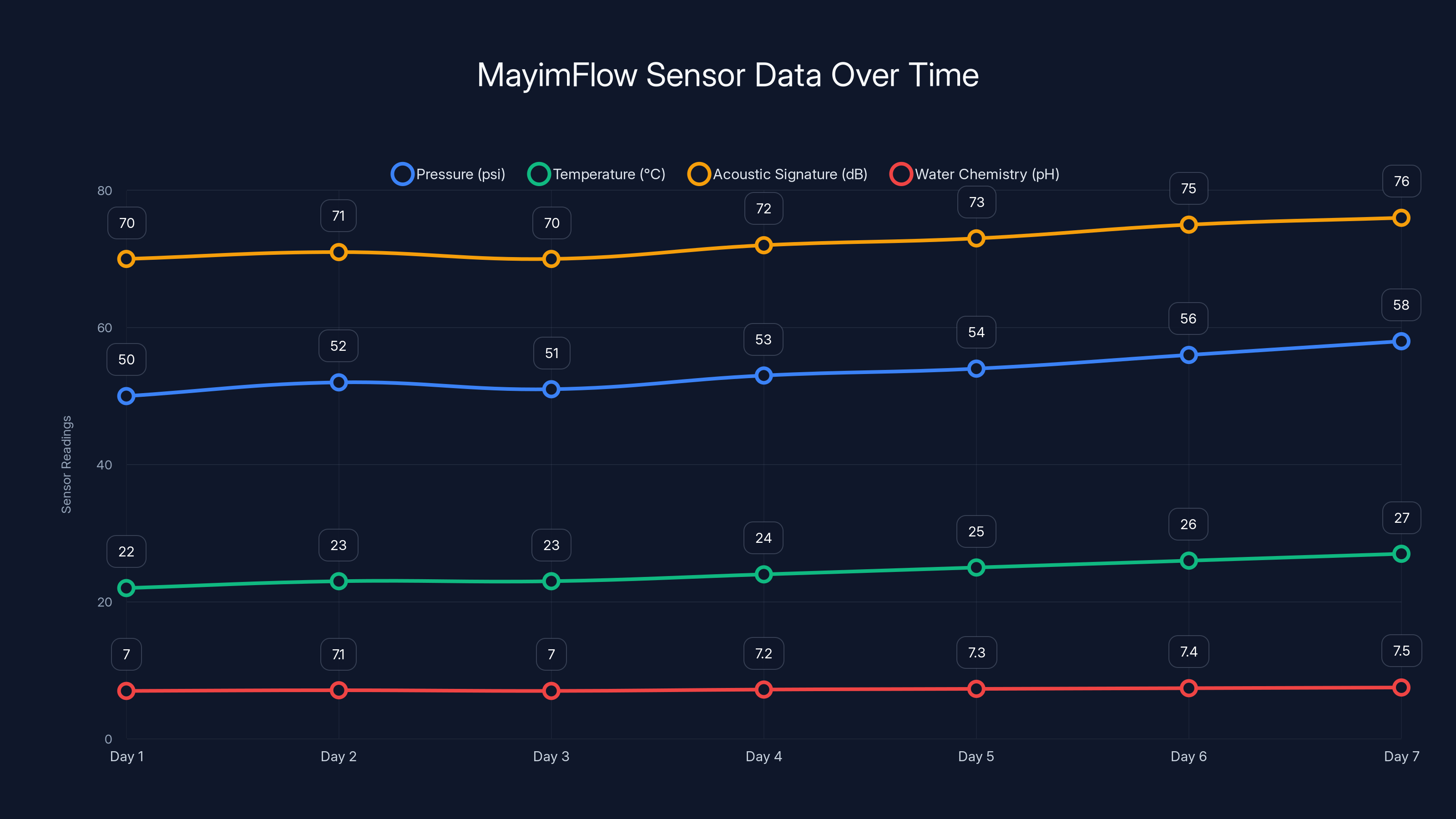

Mayim Flow's core technology combines three complementary approaches to leak prediction. First, the company deploys physical IoT sensors throughout water systems. These sensors don't just measure flow rates or pressure. They capture detailed data about system behavior, including micro-vibrations, acoustic signatures, temperature gradients, and chemical composition changes.

Second, Mayim Flow has trained machine learning models on vast historical datasets from industrial water systems. These datasets include thousands of leak events captured in real time. The models have learned the specific patterns that precede failures. They recognize the subtle changes that humans would never catch manually.

Third, the system operates at the edge, meaning computation happens locally on deployed hardware rather than sending all data to cloud servers. This approach offers multiple advantages. It provides real-time processing without network latency. It ensures data privacy since sensitive facility information doesn't leave the premises. It continues functioning even if internet connectivity drops.

The result is a system that actually works at the scale and complexity of modern data centers. Instead of humans checking for leaks periodically, the system monitors continuously. Instead of waiting for catastrophic failures, it predicts problems weeks or days before they become critical.

Khazraee emphasizes that Mayim Flow isn't trying to replace existing water monitoring infrastructure that companies might already have in place. Some data centers have invested in sophisticated sensor networks and SCADA systems. Mayim Flow can integrate with these existing setups, adding the machine learning layer that transforms raw data into actionable predictions.

For operators without existing sensors, Mayim Flow provides complete hardware and software packages. The company can install its own sensor network designed specifically for leak prediction. This modular approach means operators with different infrastructure maturity levels can adopt the solution.

The 24 to 48 hour prediction window matters enormously in practice. It's long enough for engineers to schedule maintenance during planned downtime windows. It's long enough to order replacement parts if needed. It's long enough to mobilize a response team without panic. It transforms the problem from an emergency to a management task.

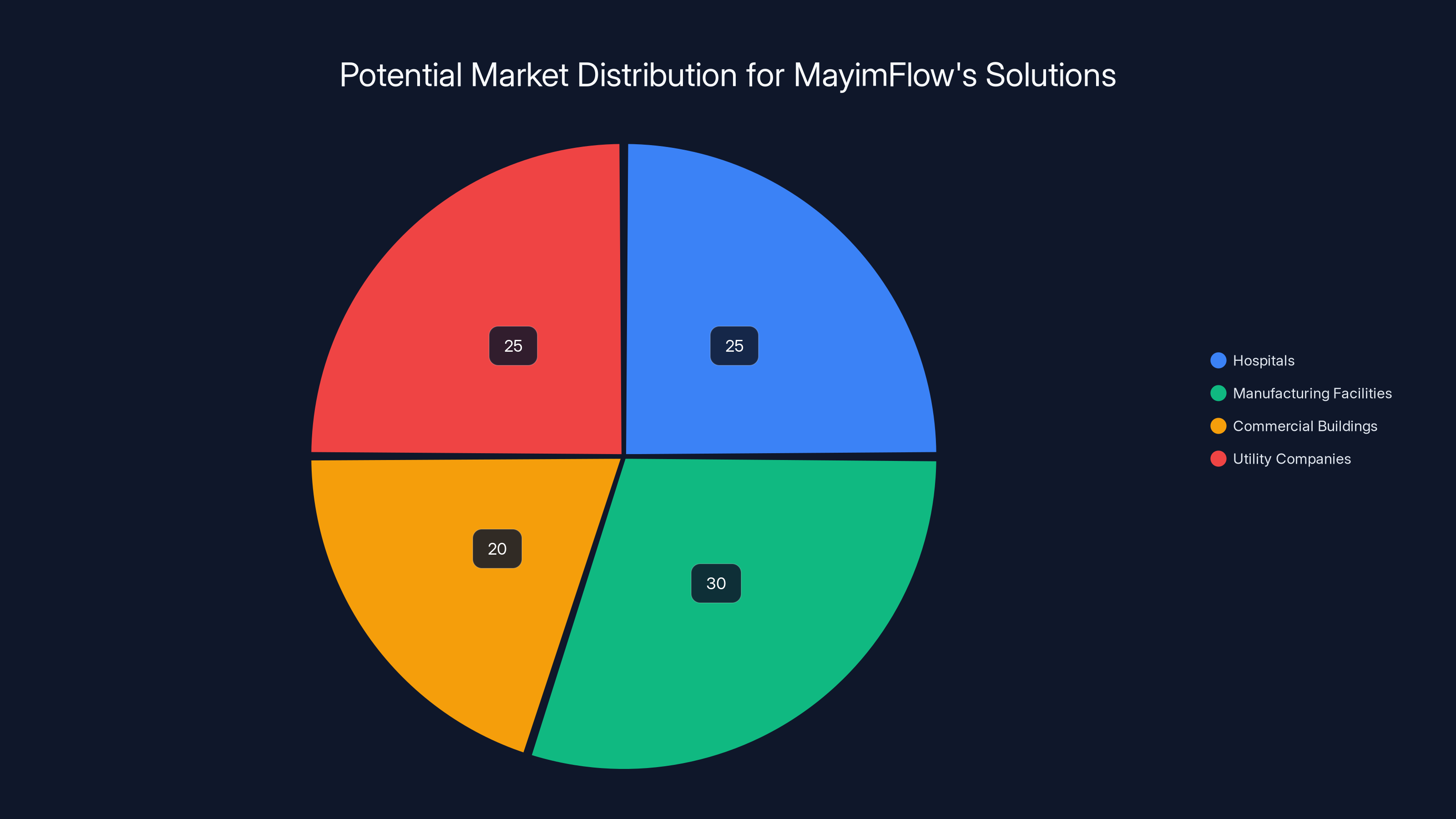

Estimated data suggests that manufacturing facilities and utility companies represent the largest market opportunities for MayimFlow's water leak solutions, each accounting for about 25-30% of the potential market.

The Market Opportunity Beyond Data Centers

While data centers are Mayim Flow's initial focus, Khazraee sees the market opportunity extending far beyond server farms. The fundamental problem the company solves applies anywhere water systems carry operational risk and financial consequence.

Hospitals represent a massive potential market. These facilities operate 24/7 and depend absolutely on reliable water and cooling systems. A water failure in a hospital isn't just expensive. It can affect patient care, disrupt critical procedures, and create safety hazards. Predictive leak detection would be particularly valuable in operating rooms and critical care areas where water damage could have life-or-death implications.

Manufacturing facilities face similar pressures. A water system failure in a semiconductor cleanroom, pharmaceutical facility, or food processing plant can destroy products, contaminate environments, and violate regulatory requirements. Many manufacturing processes depend on ultra-pure water systems that are both expensive to operate and vulnerable to contamination from leaks. Predicting failures before they happen protects product quality and regulatory compliance.

Commercial buildings and office campuses have obvious water leak problems. Property managers deal with burst pipes, failed connections, and water damage to floors and walls constantly. These incidents create tenant disruptions, property damage, and insurance claims. A system that prevents leaks before they occur would save property managers enormous headaches.

Utility companies operate vast water distribution networks. These systems serve cities, regions, and entire geographic areas. Water loss from leaks in municipal systems is staggering. Some cities lose 20% to 30% of treated water to leaks before it reaches consumers. Utilities would pay substantially for technology that helps identify and prevent these losses.

The underlying insight is that water leaks are expensive everywhere, but most organizations don't have good tools to predict them. They have reactive repair crews and insurance policies, but they lack predictive visibility. That's the opportunity Mayim Flow is pursuing.

Expanding beyond data centers also makes strategic sense for the company's growth. Data centers represent a concentrated, sophisticated customer base. Getting traction there validates the core technology. Success in data centers builds credibility for expansion into other verticals. The company can prove the concept works, establish reference customers, and refine the offering before moving into adjacent markets.

How Predictive Leak Detection Works in Practice

The technical foundation of Mayim Flow's approach relies on understanding how water systems fail and what signals precede failure. Before a pipe ruptures or a joint fails completely, the system exhibits detectable changes.

In a pressurized water line approaching failure, micro-vibrations increase in the pipe structure. The metal fatigues gradually, creating oscillations at specific frequencies that sensors can detect. Acoustic signature analysis can identify these patterns before they escalate into complete failure.

Temperature changes around a failing joint provide another signal. As structural integrity degrades, local cooling or pressure variations create measurable temperature anomalies. These are subtle, but sensors can detect them reliably.

Chemical composition changes signal problems too. As metal corrodes, corrosion byproducts appear in the water. As protective coatings fail, different elements enter the system. Water chemistry sensors can detect these changes weeks before they result in visible leaks.

Pressure patterns in the system contain information about emerging problems. A pipe beginning to fail will show pressure fluctuations and ripple patterns different from normal operation. Machine learning models trained on extensive historical data can recognize these patterns.

Flow rate anomalies matter as well. Even small leaks cause measurable changes in flow characteristics throughout the system. A branch that normally flows at exactly 100 gallons per minute might fluctuate between 98 and 102 gallons per minute as a problem develops. Sensors tuned to detect these micro-variations can flag issues early.

The power comes from analyzing these signals in combination. No single indicator is definitive. But when temperature anomalies correlate with acoustic signatures and pressure fluctuations, and when machine learning models trained on thousands of historical failures recognize the combined pattern, the signal becomes reliable.

This is where Khazraee's decades of infrastructure experience become valuable. He understands water systems deeply. He knows which sensors matter most, where they should be placed, and how to interpret the signals they produce. His team can translate that domain expertise into effective machine learning models.

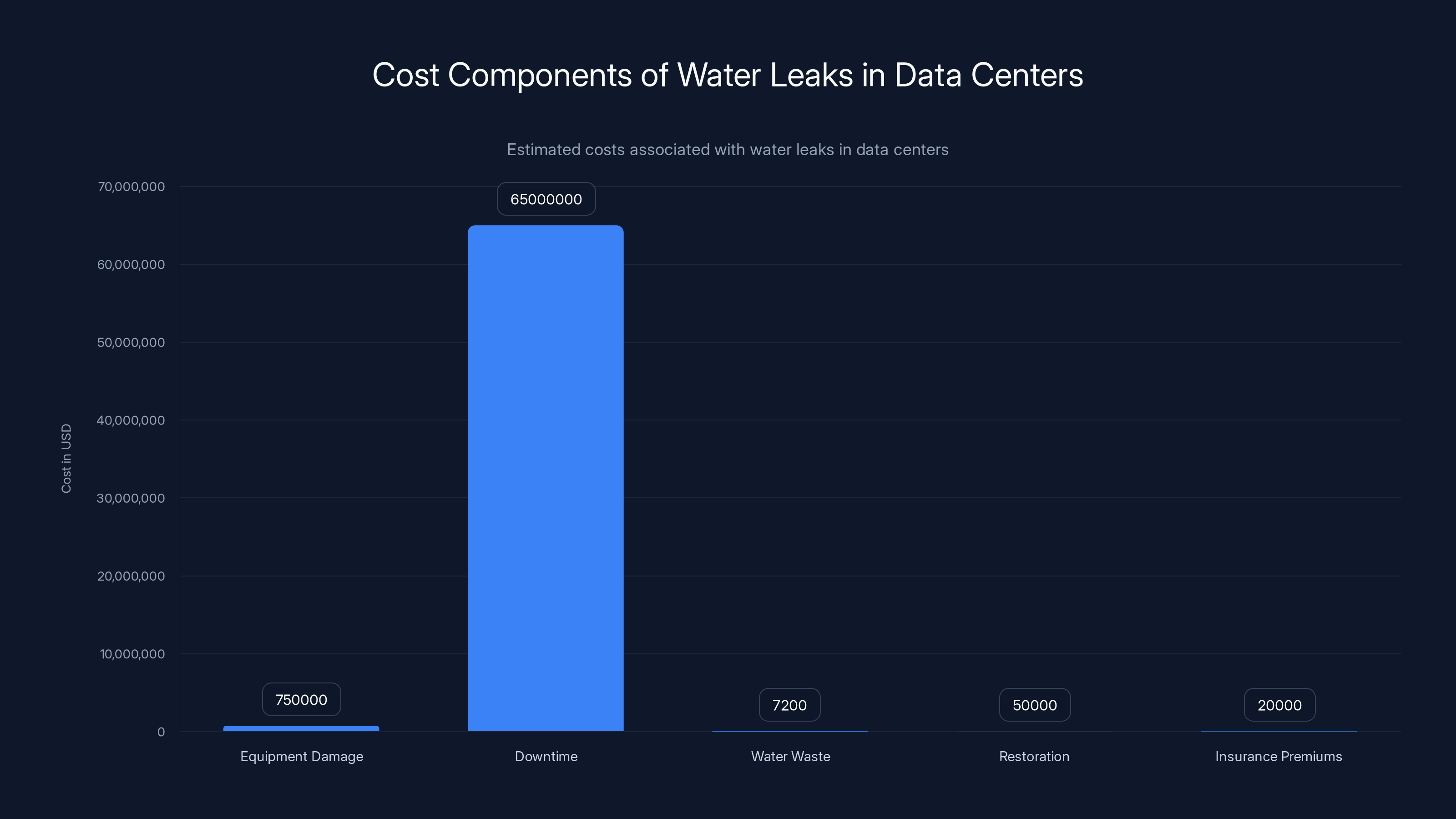

Downtime is the most significant cost component, with potential losses reaching up to $65 million. Estimated data based on typical scenarios.

Building the Team: Infrastructure Experts Who Know Water

A startup's success often depends less on the idea and more on the team executing that idea. Mayim Flow's leadership team demonstrates deep expertise in exactly the domains that matter most.

John Khazraee's 15 years building infrastructure for some of the world's largest technology companies provided the crucible where this problem became obvious to him. When you've designed and managed infrastructure at the scale of hyperscale data centers, you understand problems that smaller operators never encounter. You've seen rare failure modes. You've managed systems so complex that hidden vulnerabilities emerge constantly. You've watched expensive incidents happen because systems operated reactively.

That experience is essentially impossible to replicate from outside. You can't understand the deep challenges of data center operations without having lived them. You can't build products for this market without knowing the specific pain points intimately.

Jim Wong brings complementary expertise in data center operations and strategy. His decades in the industry mean he understands not just the technical challenges but the business dynamics. He knows what data center operators actually value, what they'll pay for, and how they make purchasing decisions. He's probably witnessed hundreds of water-related incidents and understands their cost implications.

Ray Lok's background in water management and IoT infrastructure provides the third critical piece. Building IoT systems that work reliably at scale is genuinely difficult. Most IoT deployments struggle with sensor reliability, data quality, network connectivity, and hardware durability. Someone with deep experience in this domain knows how to avoid the pitfalls that sink other projects.

This isn't a team of researchers with theoretical knowledge. It's a team of practitioners who've built real systems that matter. They've probably failed multiple times. They've learned through hard experience what works and what doesn't.

The quality of the team is evident in the fact that Khazraee has turned down multiple offers from major technology companies to pursue Mayim Flow. These offers likely came with significant financial packages, prestige, and security. Walking away from that to build a startup requires conviction. That conviction comes from believing the problem is genuinely important and that the team can solve it.

The Economics of Water Leak Prevention

Understanding the financial case for Mayim Flow requires quantifying the cost of water leaks. The numbers are large enough that they justify substantial investment in prevention.

The direct costs of a major water leak in a data center start with equipment damage. A single server rack can cost

Secondary damage multiplies costs. Water that reaches electrical systems can create fire hazards and force safety shutdowns. Corrosion from water damage can affect systems months after the incident. Cleaning and restoration costs add up rapidly. Emergency repair contractors charge premium rates for urgent response.

Downtime represents the largest cost component. When a data center experiences a service interruption, every minute of downtime affects customers. For a large cloud provider, downtime might cost

Even partial service degradation creates costs. If a facility can only operate at 70% capacity while repairs occur, that lost capacity has economic value. Revenue is lost. Competitors capture business. Customer relationships suffer.

Water waste represents another cost dimension. A leak of 1,000 gallons per hour adds up to 24,000 gallons daily. Over a month, that's 720,000 gallons. At typical water treatment and disposal costs of

The insurance and regulatory implications matter too. Each water incident gets reported to insurance carriers. Multiple claims increase premiums. Some underwriters will stop covering facilities with bad track records. Regulatory agencies might impose restrictions or fines for water waste.

Putting these numbers together, a single significant water leak could easily cost

Compare that to the cost of a predictive monitoring system. If Mayim Flow charges, say,

Better yet, the system provides ongoing benefits beyond incident prevention. It optimizes water usage. It helps facility managers understand their water systems better. It provides historical data that improves planning and maintenance. These benefits compound over time.

Estimated data shows how MayimFlow monitors sensor readings over a week, detecting anomalies before they lead to failures.

Integration Strategies: Fitting Into Existing Infrastructure

One of the smartest aspects of Mayim Flow's approach is its flexibility around integration. Not every data center has the same infrastructure setup. Some have sophisticated SCADA systems and extensive sensor networks. Others operate with minimal monitoring. Mayim Flow needs to work with all of them.

For facilities with existing monitoring infrastructure, Mayim Flow acts as an intelligence layer on top. The company can integrate with SCADA systems, pulling data from existing sensors without requiring replacement. The machine learning models process this data stream and generate predictions. This approach minimizes installation complexity and cost while providing maximum value.

Facilities without existing sensors need a complete solution. Mayim Flow provides the hardware and software together. The company handles sensor selection, placement strategy, installation, configuration, and calibration. This end-to-end approach ensures the system works from day one.

Maintenance and support matter enormously for this type of system. Sensors can fail. Software needs updates. Algorithms require occasional retraining on new data. Mayim Flow has to provide ongoing support that keeps the system functioning reliably. Facilities expect that when they buy the system, someone will maintain it.

Data integration is another critical consideration. Many data centers run proprietary systems that don't share data easily. Network architecture might isolate operational technology from IT systems. Physical plant systems might operate independently. Getting data flowing from these isolated systems into Mayim Flow's analysis pipeline requires careful integration work.

The company also needs to address connectivity constraints. Not every water system location has reliable network connectivity. Some areas in data centers are electrically noisy, affecting wireless signals. Some locations are physically inaccessible during normal operations. System design needs to account for these real-world constraints.

Security considerations loom large. Data center operators treat their facilities as critical infrastructure. They enforce strict access controls. They're skeptical of new software running on their networks. Mayim Flow needs to address security concerns directly, proving that the system doesn't create vulnerabilities.

Scaling Production and Manufacturing

Moving from a proof-of-concept to a product that thousands of data centers can use requires scaling manufacturing and support operations. Mayim Flow needs to solve several practical problems.

Sensor manufacturing at scale presents challenges. Building thousands of reliable sensors that function consistently across different environments requires quality control processes. Components need sourcing from stable suppliers. Production capacity needs to match demand without creating inventory glut.

Software deployment at scale requires robust infrastructure. Mayim Flow's systems need to handle deployments across hundreds or thousands of facilities. Updates need to roll out smoothly without disrupting operations. Monitoring needs to detect problems before they affect customer systems.

The support and service organization needs to scale alongside product adoption. Each new customer needs onboarding support. Problems need troubleshooting. Technical expertise needs to be available when customers have questions.

Training is another scaling challenge. Data center operators need to understand how the system works, what the predictions mean, and how to act on the information. Mayim Flow needs training materials, technical documentation, and perhaps on-site training services.

Manufacturing partnerships might be necessary. For IoT hardware, many startups partner with established manufacturers rather than building their own facilities. This approach reduces capital requirements and accelerates scaling. It also brings manufacturing expertise that startups typically lack.

The supply chain needs resilience. A single component shortage could constrain production. Mayim Flow needs dual sourcing strategies, buffer inventory, and alternative designs to protect against supply chain disruptions.

Hyperscale data centers can use up to 10 million gallons of water daily, highlighting the significant water demands of modern computing infrastructure. Estimated data.

The Competitive Landscape and Market Position

Mayim Flow operates in a market segment that's relatively underdeveloped. Traditional facility management companies offer reactive leak detection. SCADA system vendors provide monitoring platforms but not specialized leak prediction. Water technology companies focus on treatment and conservation but not facility-level prediction.

This lack of competition is actually revealing. It suggests the market hasn't yet recognized the economic opportunity. As more data centers focus on operational efficiency and risk management, demand for predictive solutions will grow.

The company's competitive advantages are substantial. Khazraee's infrastructure background and his team's collective experience create defensible knowledge. They understand water systems and data center operations better than most potential competitors. The proprietary datasets they've collected for model training represent a moat. Competitors would need to gather similar data, which takes time and access to operational systems.

The intellectual property around the prediction algorithms and edge deployment architecture also provides protection. While individual algorithms aren't typically patentable in isolation, the combination of hardware design, software architecture, and machine learning approaches might be defensible.

Brand and trust matter in infrastructure decisions. Once Mayim Flow proves its system works across multiple reference customers, that track record becomes a significant competitive advantage. Facility managers trust vendors who have earned their reputation through real-world performance.

First-mover advantage could be significant. If Mayim Flow captures the data center market early, they'll accumulate more operational data than competitors. More data makes models better. Better models make predictions more accurate. Accuracy creates customer loyalty. This positive feedback loop becomes harder for competitors to break into over time.

The Water Scarcity Context: Why This Matters Now

Khazraee's motivation to pursue Mayim Flow is partly rooted in environmental and resource concerns that have become increasingly urgent. Water is becoming a genuine constraint in many parts of the world.

Data centers consume enormous water volumes in regions that are already water-stressed. California, Arizona, and other regions hosting major data center clusters are experiencing drought conditions. The Middle East, where some major cloud providers want to expand facilities, has extreme water scarcity. As climate change progresses, water stress will only increase in most regions.

Water waste in data centers isn't just an efficiency problem. It's a sustainability issue. Preventing leaks means less water enters treatment systems unnecessarily. It means less pressure on local water supplies. It means more water available for agricultural and domestic uses.

Regulatory pressure around water usage is increasing. Some jurisdictions now require large water consumers to implement monitoring and conservation measures. Future regulations might demand even stricter accountability. Being ahead of regulatory curves provides competitive advantages.

The economic case for water conservation has strengthened too. As water becomes scarcer and more expensive, saving water directly improves operating costs. Predictive systems that optimize water usage become increasingly valuable.

From a business perspective, this broader context matters. Data center operators increasingly care about environmental metrics. Cloud providers advertise their commitment to sustainability. Customers want to know that companies are managing resources responsibly. A system that prevents waste and reduces water usage aligns with these values.

Estimated data shows MayimFlow's progression through key growth milestones from startup to market leader, highlighting the importance of recognition, customer validation, and strategic partnerships.

Real-World Application: How Mayim Flow Works in Practice

Imagining how Mayim Flow operates in a specific scenario helps illustrate its value. Consider a large hyperscale data center facility with complex water systems supporting multiple cooling loops.

Mayim Flow deploys sensors throughout the facility's water infrastructure. Sensors measure pressure, flow rate, temperature, acoustic signatures, and water chemistry at strategic points. The system collects data continuously, 24 hours daily.

Over days and weeks, the system learns normal operating patterns for this particular facility. It understands that pressure fluctuates between certain values during different times of day. It recognizes that temperature varies based on ambient conditions and cooling demand. It learns the acoustic signature of normal operation.

Then, one Tuesday morning, subtle changes begin. A connection point in a cooling line starts experiencing slightly elevated pressure fluctuations. Temperature around the connection rises imperceptibly. Acoustic signatures shift. Water chemistry shows trace amounts of metals that shouldn't be present.

The machine learning model, trained on thousands of historical failures, recognizes this pattern. It flags a problem. Not an immediate leak, but something that will become one within days if uncorrected.

The system generates an alert. The facility manager receives a notification: "Elevated failure probability for cooling loop 3, junction point 7. Recommended action: Schedule maintenance within 48 hours."

The manager looks at the facility schedule. The backup cooling loop can run independently if necessary. She schedules maintenance for the following night during the lowest-traffic period. The maintenance crew arrives with replacement parts ready. They isolate the affected junction, replace the failing connection, and test the system.

The incident is resolved with no service disruption. Equipment remains undamaged. No emergency response was needed. The facility continues operating smoothly.

Compare this to the reactive scenario. Without predictive monitoring, the failure might go unnoticed for days. The connection might rupture suddenly at 3 AM. Water floods the area, potentially damaging equipment. The facility manager gets an urgent call. Emergency crews mobilize. Depending on the extent of damage, the facility might shut down one or more cooling loops, reducing capacity.

The difference between these scenarios is enormous. One involves planned maintenance. The other involves crisis management. One costs thousands. The other costs millions. One is preventable with the right technology. The other is avoidable only through luck.

Broader Implications for Infrastructure Reliability

Mayim Flow represents a broader trend in infrastructure management toward predictive, data-driven approaches. Instead of reactive maintenance triggered by failures, modern facilities are shifting toward predictive maintenance driven by sensor data and machine learning.

This shift applies beyond water systems. Electrical systems, mechanical systems, cooling systems, and other infrastructure components are increasingly monitored and analyzed. Sensors become cheaper and more capable. Machine learning models become more sophisticated. The economics of predictive maintenance improve constantly.

For data center operators, this evolution is essential. As facilities grow larger and more complex, reactive maintenance becomes increasingly risky. Downtime becomes more expensive. Infrastructure interdependencies create cascading failure risks. Only through comprehensive predictive systems can operators maintain reliability at scale.

The broader energy and utility industry faces similar pressures. As grids become more complex and demand more elastic, predictive systems that prevent failures become more valuable. Water utilities dealing with aging infrastructure and climate stress need better tools for identifying problems before they happen.

Cities and municipalities investing in smart infrastructure are discovering that sensor networks combined with machine learning create enormous value. Predictive systems for water mains, stormwater systems, and wastewater treatment improve efficiency and reliability simultaneously.

Mayim Flow's success in data centers could establish a model that extends across many infrastructure domains. The core principle remains the same: collect comprehensive data about system behavior, train models on historical failure data, and use those models to predict problems before they become critical. Different industries can apply the same approach to their specific challenges.

The Growth Trajectory: From Startup to Market Leader

Mayim Flow's path from startup to market leader involves several critical milestones. The company has already achieved recognition by winning the Built World stage at Tech Crunch Disrupt, which provides visibility and credibility in its target market.

The next phase involves reference customers and proof points. Every company at this stage needs customers willing to adopt an unproven product in exchange for early discounts or other incentives. Those early adopters provide the real-world validation that makes selling to subsequent customers easier.

Expanding from initial reference customers to broader market adoption requires addressing objections and building confidence. Potential customers want assurance that the product works reliably. They want evidence that similar facilities have had positive experiences. They want support services and guarantees.

Building direct sales capabilities matters at this phase. Startup founders are often great at explaining their vision, but scaling requires a sales organization. Mayim Flow needs sales engineers who understand both the technology and the customer needs. It needs processes for qualifying prospects, building proposals, and closing deals.

The company also needs to establish partnerships. Large data center operators often prefer working with established vendors rather than startups. Partnering with systems integrators, facility management companies, or major equipment suppliers could accelerate market adoption.

As the company grows, international expansion becomes relevant. Large data centers operate globally. Initial success in North American markets could extend to EMEA, APAC, and other regions. Each region brings different regulatory requirements, customer preferences, and competitive dynamics.

Eventual consolidation is likely. As the infrastructure monitoring and predictive maintenance market matures, larger companies will acquire successful startups like Mayim Flow. This could provide founders and investors with liquidity events. Alternatively, if Mayim Flow grows large enough to remain independent, it could eventually become a publicly traded company.

Technical Considerations for Implementation

While Mayim Flow's value proposition is compelling, implementing the system in real facilities involves technical considerations and challenges worth examining.

Sensor placement strategy significantly affects system effectiveness. Placing sensors at the most critical junctions and connections maximizes value, but requires deep understanding of facility water systems. Poor placement leaves vulnerabilities. A system that can guide placement decisions through analysis of facility blueprints and historical incident data would be valuable.

Data quality directly impacts model accuracy. Sensors can drift, malfunction, or produce noisy data. The system needs robust mechanisms for identifying bad data and handling it appropriately. This might involve redundant sensors at critical points, statistical analysis to identify outliers, and mechanisms to validate predictions before generating alerts.

Algorithm retraining and updating ensures predictions remain accurate as facilities change. New equipment, modified pipe routing, upgraded systems, and other changes alter normal operating baselines. The system needs mechanisms to adapt models to these changes rather than generating false alarms based on old assumptions.

False positive management is critical. If the system generates too many false alarms, facility managers will stop trusting it. Worse, they'll ignore real alerts in the noise of false ones. The threshold for generating alerts must be calibrated carefully to balance sensitivity and specificity.

Integration with existing building management systems requires solving various technical challenges. Different facilities use different systems. Data formats, communication protocols, and security requirements vary. Mayim Flow needs flexibility to handle this variety.

Competitive Responses and Market Evolution

As Mayim Flow gains traction, competitive responses are inevitable. Larger companies will notice the market opportunity and develop competing solutions.

Traditional SCADA vendors might add predictive analytics capabilities to their platforms. They have existing relationships with data center operators and deep platform integration. They could extend their offerings to include water leak prediction.

Manufacturers of facility monitoring equipment could integrate similar capabilities. Companies making sensors, control systems, and monitoring hardware might partner with machine learning vendors or acquire analytics startups.

Big technology companies with resources and existing data center relationships could build proprietary solutions. Companies like Amazon, Google, and Microsoft might develop internal tools optimized for their own facilities. They might eventually commercialize these tools as service offerings.

Water technology companies with industry expertise could develop competing solutions. Companies focused on water treatment, conservation, and management understand water systems deeply. They could add predictive capabilities to their product lines.

Startups focused on facility analytics broadly could add water-specific capabilities. General infrastructure analytics platforms might expand their offerings to include water leak prediction.

The competitive landscape will probably become more crowded as the market opportunity becomes clear. However, Mayim Flow's early-mover advantage, specialized expertise, and focus provide substantial defensibility. Companies that establish strong positions early typically maintain them as markets mature.

Khazraee's Vision: Beyond the Initial Product

Khazraee's background and motivations suggest his vision for Mayim Flow extends beyond simply selling water leak detection systems. His childhood experience with frugality and efficiency, combined with his infrastructure expertise, point toward a larger ambition.

He sees water as a critical resource that modern infrastructure manages poorly. He sees waste everywhere: in data centers, in cities, in manufacturing. He sees inefficiency embedded in systems that don't monitor and optimize continuously.

His comment about water becoming one of the big issues in the world reflects this broader perspective. Climate change is increasing water stress in most regions. Population growth increases demand. Infrastructure aging increases waste. These trends will only intensify.

A company that becomes the standard platform for water system monitoring and leak prediction could eventually expand into broader water management. Optimization recommendations. Conservation strategies. Regulatory compliance support. Integrated water analytics across an organization's entire footprint.

This vision aligns with how infrastructure is evolving more broadly. Connected systems with comprehensive monitoring. Machine learning-driven optimization. Predictive maintenance replacing reactive troubleshooting. Real-time alerts replacing manual inspection.

Khazraee's decision to build Mayim Flow rather than accept offers from major tech companies reflects conviction in this vision. Large companies operate according to quarterly earnings pressures and organizational inertia. Startups can pursue ambitious visions without those constraints.

Successfully executing that vision requires several things: a product that solves real problems for customers. A market that's ready to adopt it. A team capable of building sustainable business. Capital to scale operations. Mayim Flow appears to have all of these components.

Conclusion: The Convergence of Infrastructure, Data, and Sustainability

Mayim Flow's emergence as a business reflects deeper trends in how modern infrastructure operates. Sensor technology has become affordable enough to deploy comprehensively. Machine learning has become capable enough to extract value from sensor data. The costs of infrastructure failure have become high enough that prevention justifies investment in monitoring.

Data centers represent the perfect proving ground for this approach. They're complex, they're expensive to operate, they're high-stakes (downtime is costly), and they're managed by sophisticated teams who understand technology. Success here validates the approach.

The broader implications extend far beyond data centers. Every facility that depends on water systems faces the same risks. Cities managing municipal water infrastructure. Hospitals ensuring critical system reliability. Manufacturing plants protecting product quality. Utilities managing vast distribution networks. Utilities suffering from aging infrastructure. All of them could benefit from predictive monitoring.

What Khazraee is building isn't just a product company. It's a company that's helping solve one of the world's growing problems: managing scarce water resources efficiently. It's helping critical infrastructure become more reliable. It's helping reduce waste.

These aren't small problems. They're infrastructure challenges that affect billions of people. Companies that solve these challenges at scale create enormous value—both for themselves and for the world.

Mayim Flow's journey from concept to market leader hasn't concluded yet. The company is still in early stages. Real challenges remain: scaling manufacturing, expanding sales, managing growth, competing effectively. But the opportunity is clear, the team is strong, and the problem is genuine.

In the infrastructure technology space, that combination often leads to success. Mayim Flow has a realistic shot at becoming the standard platform for predictive water monitoring. That would represent a significant achievement and genuine impact.

FAQ

What is water leak prediction in data centers?

Water leak prediction uses IoT sensors combined with machine learning algorithms to detect early warning signs that a water system is about to fail. Instead of discovering leaks after they've already caused damage, predictive systems identify problems 24 to 48 hours before they become critical, allowing facility managers to schedule repairs during planned maintenance windows rather than responding to emergencies.

How does Mayim Flow's leak detection system actually work?

Mayim Flow deploys sensors throughout a facility's water infrastructure that continuously measure pressure, flow rate, temperature, acoustic signatures, and water chemistry. The system's machine learning models, trained on historical data from thousands of water system failures, analyze these sensor signals to identify patterns that precede failures. When the system detects a concerning pattern, it generates an alert, giving facility managers time to address the problem before it becomes critical.

What are the main benefits of predictive water monitoring for data centers?

The primary benefits include preventing expensive downtime (data center outages cost hundreds of thousands of dollars per hour), protecting equipment from water damage, reducing emergency response costs, optimizing water usage, and improving facility reliability. A single prevented catastrophic failure typically pays for years of monitoring costs, making the system highly cost-effective for most large facilities.

How much does implementing Mayim Flow cost for a typical data center?

Costs vary based on facility size and existing infrastructure, but predictive monitoring systems typically range from

Can Mayim Flow integrate with existing water monitoring systems?

Yes, one of Mayim Flow's key advantages is its flexibility in integration. For facilities with existing SCADA systems or sensor networks, Mayim Flow acts as an intelligence layer that uses machine learning to analyze data from those existing systems. For facilities without existing monitoring infrastructure, Mayim Flow provides complete hardware and software solutions.

Beyond data centers, what other applications does Mayim Flow target?

Khazraee has indicated that Mayim Flow's technology applies to any facility with water systems that carry operational or financial risk. This includes hospitals (where water failures could affect patient care), manufacturing plants (where water failures could damage products or violate cleanroom requirements), commercial buildings, municipalities managing water distribution networks, and utilities struggling with aging infrastructure.

How does predictive water monitoring relate to water conservation and sustainability?

By preventing leaks before they occur, predictive systems reduce water waste substantially. Data center leaks can waste hundreds of thousands of gallons monthly if left undetected. More broadly, as water scarcity increases due to climate change and population growth, infrastructure that optimizes water usage becomes increasingly valuable from both economic and environmental perspectives.

What makes Mayim Flow different from traditional reactive leak detection approaches?

Traditional approaches rely on manual inspection or discovering leaks only after they've already caused damage. Mayim Flow's predictive approach uses continuous monitoring and machine learning to catch problems before they become critical. This transforms water system management from reactive crisis response into proactive maintenance planning.

Why did John Khazraee turn down offers from major tech companies to build Mayim Flow?

Khazraee's 15 years of infrastructure experience at IBM, Oracle, and Microsoft exposed him to the significant costs and inefficiencies of reactive water management in data centers. His conviction that predictive water monitoring could solve a genuine, high-impact problem motivated him to pursue Mayim Flow rather than continue working at larger organizations where he couldn't pursue this specific vision.

What competitive advantages does Mayim Flow have as it scales?

The company benefits from several defensible advantages: deep expertise in both water systems and data center operations from its leadership team, proprietary machine learning models trained on extensive historical failure data, established relationships with reference customers who validate the product, and first-mover advantage in a market segment that hasn't yet seen direct competition from larger incumbents.

Key Takeaways

- MayimFlow uses IoT sensors and machine learning to predict water system failures 24-48 hours before they occur, transforming crisis management into scheduled maintenance

- A single undetected water leak in a hyperscale data center can cost $5-20 million in equipment damage, downtime, and secondary effects

- Founder John Khazraee's 15 years of infrastructure experience at IBM, Oracle, and Microsoft directly informed his understanding of reactive water management problems

- The technology extends beyond data centers to hospitals, manufacturing facilities, commercial buildings, and municipalities managing water infrastructure

- Early-stage water system failures show detectable changes in pressure, temperature, acoustic signatures, and chemical composition before becoming critical

Related Articles

- Best AI Chatbots for Beginners: Complete Guide [2025]

- The Highs and Lows of AI in 2025: What Actually Mattered [2025]

- JuicyChat.AI: Exploring the Future of AI Conversations [2025]

- Is Artificial Intelligence a Bubble? An In-Depth Analysis [2025]

- [2026] Best AI Productivity Tools

- [2025] How Bird Monitoring AI Software is Revolutionizing Wildlife Conservation

![MayimFlow: Preventing Data Center Water Leaks Before They Happen [2025]](https://tryrunable.com/blog/mayimflow-preventing-data-center-water-leaks-before-they-hap/image-1-1766939748967.jpg)